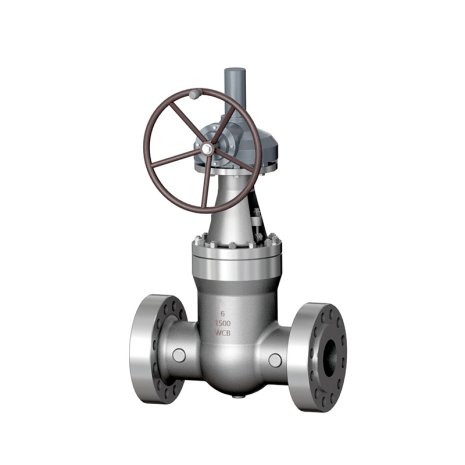

Pressure seal gate valves are characterized by a traveling wedge, which is moved with the operation of the stem nut. The wedge travels perpendicular to the direction of the flow.

Gate valves are double sealing design, it usually have a minimum pressure drop when fully open, provide tight shut-off when fully closed.

Pressure seal gate valves are used for high pressure service, typically for pressures above 100 bar. The unique feature of the pressure seal bonnet is that the body-bonnet joints seal improves as the internal pressure within the valve increases.

The main applications are: petrochemical industry, steam circuits, boiler circulation, oil and gas applications, power stations

Common used types of medium encountered are: steam, condensate, boiler feedwater

Typical pressure rating of the valve is 900, 1,500 and 2,500 pounds.

The range of JLPV gate valve design is as follows:

1.Size: 2” to 48” DN50 to DN1200

2.Pressure: Class 900lb to 2500lb PN160-PN420

3.Material: Carbon steel and stainless steel and other special materials.

NACE MR 0175 anti-sulfur and anti-corrosion metal materials

4.Connection ends: ASME B 16.5 in raised face(RF), Flat face(FF) and Ring Type Joint (RTJ)

ASME B 16.25 in butt welding ends.

5.Face to face dimensions: conform to ASME B 16.10.

6.Temperature: -29℃ to 580 ℃

JLPV valves can be manufactured in all kinds of materials to meet different requirements from clients, especially in NACE standard.

JLPV valves can be equipped with gear operator, pneumatic actuators, Hydraulic actuators, Electric actuators,bypasses,locking devices,chainwheels,extended stems and many others are available to meet the customers’ requirements.